|

|

|||

MOTORI AC - 2

|

|||

|

|||

|

|

|||

|

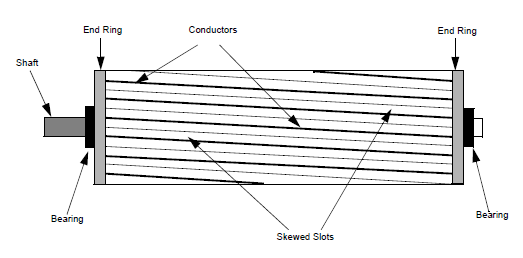

ROTORE

Il rotore Ŕ composto da diverse

lamine sottili di acciaio con barre equidistanti, che sono fatte di alluminio o

rame, lungo la periferia. Nel tipo di rotore pi¨ popolare (rotore a gabbia di

scoiattolo), queste barre sono collegate meccanicamente ed elettricamente alle

estremitÓ tramite l'uso di anelli. Quasi il 90% dei motori a induzione ha rotor

a gabbia di scoiattolo. Questo perchÚ il rotore a gabbia di scoiattolo ha una

costruzione semplice e robusta. Il rotore Ŕ costituito da un nucleo cilindrico

laminato con scanalature parallele poste assialmente per contenere i

conduttori. Ogni scanalatura contiene una barra di rame, alluminio o lega.

Queste barre del rotore sono permanentemente cortocircuitate ad entrambe le

estremitÓ mediante anelli terminali, come mostrato nella Figura 2. Questo

insieme totale assomiglia all'aspetto di una gabbia di scoiattolo, da cui il

rotore prende il nome. Le scanalature del rotore non sono esattamente parallele

all'albero. Invece, sono inclinate per due motivi principali. Il primo motivo Ŕ rendere il

motore pi¨ silenzioso riducendo il ronzio magnetico e per diminuire le

armoniche delle scanalature. Il secondo motivo Ŕ aiutare a

ridurre la tendenza al bloccaggio del rotore. I denti del rotore tendono a

rimanere bloccati sotto i denti dello statore a causa dell'attrazione magnetica

diretta tra i due. Questo accade quando il numero di denti dello statore Ŕ

uguale al numero di denti del rotore. Il rotore Ŕ montato sull'albero

utilizzando cuscinetti ad entrambe le estremitÓ; un'estremitÓ dell'albero Ŕ

normalmente mantenuta pi¨ lunga dell'altra per guidare il carico. Alcuni motori

possono avere un albero ausiliario sul lato non motore per il montaggio di

dispositivi di rilevamento della velocitÓ o della posizione. Tra lo statore e

il rotore, esiste un gap d'aria, attraverso il quale, per induzione, l'energia

viene trasferita dallo statore al rotore. La coppia generata costringe il

rotore e quindi il carico a ruotare. Indipendentemente dal tipo di rotore

utilizzato, il principio impiegato per la rotazione rimane lo stesso.

FIGURE 2: TIPICO ROTORE A GABBIA DI SCOIATTOLO

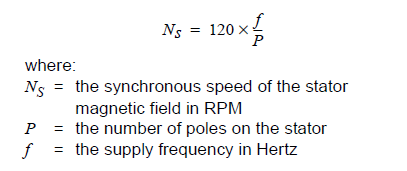

VelocitÓ di un Motore a Induzione

Il campo magnetico creato nello statore ruota a una velocitÓ sincrona (NS) e' definito dalla seguente formula:

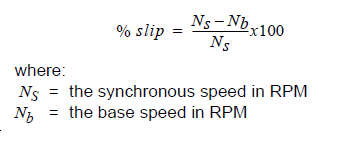

Il campo magnetico prodotto nel

rotore a causa della tensione indotta Ŕ di natura alternata. Per ridurre la

velocitÓ relativa rispetto allo statore, il rotore inizia a girare nella stessa

direzione del flusso dello statore e cerca di raggiungere il flusso rotante.

Tuttavia, nella pratica, il rotore non riesce mai a "raggiungere" il

campo dello statore. Il rotore gira pi¨ lentamente rispetto alla velocitÓ del

campo dello statore. Questa velocitÓ Ŕ chiamata VelocitÓ Base (Nb). La differenza tra NS e Nb Ŕ

chiamata scorrimento (slip). Lo scorrimento varia con il carico. Un aumento del

carico causerÓ un rallentamento del rotore o un aumento dello scorrimento. Una

diminuzione del carico causerÓ un aumento della velocitÓ del rotore o una

diminuzione dello scorrimento. Lo scorrimento Ŕ espresso come percentuale e pu˛

essere determinato con la seguente formula:

|

|

||

|

|

|||

|

|

|||

|

|

|||